What We Do

Olayan Descon dominates static equipment manufacturing, driven by advanced engineering, cutting-edge technology, and unmatched expertise

Manufacturing

Recognized as leading manufacturer, Olayan Descon has produced various kinds of static equipment in the Kingdom in accordance with ASME, TEMA, ANSI, API and other relevant codes and practices. Having state of the art engineering office equipped with latest design software like Pro-Vessel are used for design & detail engineering. Complete vessel including component design, preparation of shop fabrication and as built drawings is accomplished on CAE / CAD & Micro-station. Olayan Descon’s top of the line mechanical workshop is equipped with all modern and state of the art machinery and equipment for fabrication, welding, stress relieving, pipe bending and other related activities.

Pressure Vessels & Columns

Manufacturing services for pressure equipment are offered through latest design computing techniques, state-of the- art fabrication processes, advanced procurement system and stringent QA/QC norms to ensure better workmanship and quality. Olayan Descon provides a complete range of manufacturing services starting from Design up to Delivery, for equipment like Pressure Vessels and Columns, The Design, Detailed Engineering, Preparation of shop fabrication drawings and as built drawings, is accomplished on AutoCAD using latest available software. Materials including plates, dished ends, fittings and consumables are procured through approved vendors in local as well as overseas markets of Europe, Far East and US. All fabrication processes including marking, cutting, rolling, bending and welding are carried out in-house, Hydro-testing, Pneumatic testing, Magnetic particle testing, dye penetrate testing and localized post weld heat treatment is also carried out through experienced quality assurance and control team within the company.

Heat Exchangers

Quality control procedures are enforced at all stages right from design to erection to ensure a quality product. High cadre of fabrication professionals, including a number of qualified welders and a strong technical backup, extends or strengths to Fabricate Shell & Tube Heat Exchangers and Air Fin Coolers with the highest degree of engineering standards. For Shell & Tube Heat Exchangers and Air Fin Coolers, Olayan Descon offers services for:

- Mechanical Design

- Material Procurement

- Fabrication

- Testing and Painting

Shop & Site Storage Tanks

Olayan Descon is capable to undertake medium to heavy plate work involving different kinds of non-pressure equipment used in Cement, Soda Ash, Fertilizer, Chemical, Petro-chemical, Desalination, Power and Oil & Gas Plants. Olayan Descon, with its relentless pursuit of excellence in the Manufacturing of Storage Tanks, Bins, Hoppers, Stacks and Ducts is providing services for Design & Detailed Engineering, Procurement of material, Fabrication and Installation to practically all the industries including Cement, Chemical, Petro-Chemical, Fertilizer and Oil & Gas.

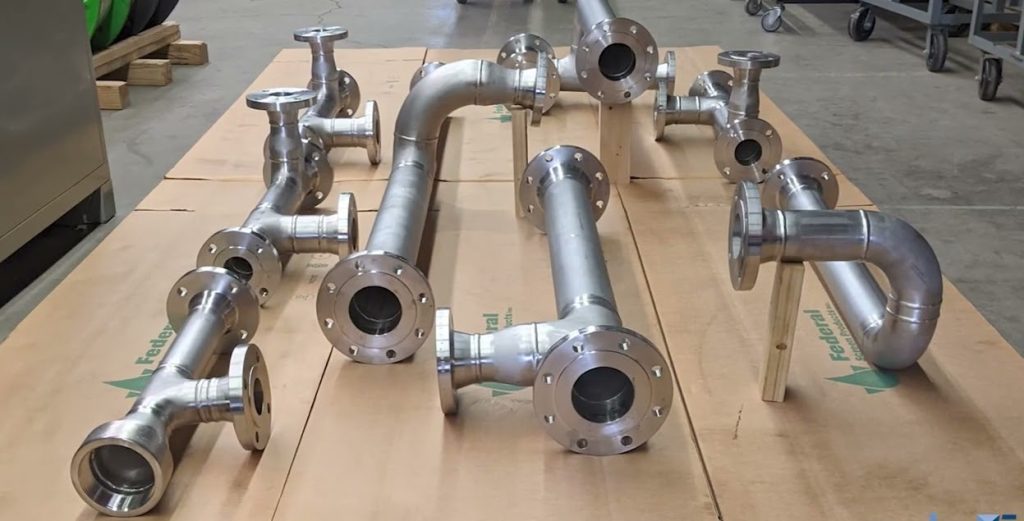

Piping Spools

Low & High-pressure piping and Process piping is one of the main activities where Olayan Descon has established an impressive track record. Olayan Descon provides a wide array of services ranging from Minor Modification to Turnkey Process Piping Networks within plant or plant-to-plant. Olayan Descon has been authorized by ASME to fabricate Pressure Piping & Power Piping under “PP” Stamp. All services are offered through experienced piping engineers, skilled fabricators, and qualified welders. Process piping projects are carried out in accordance with recognized international Standards (i.e. ANSI B31.1, B31.3, B31.4, B31.8, etc.) and client specifications.

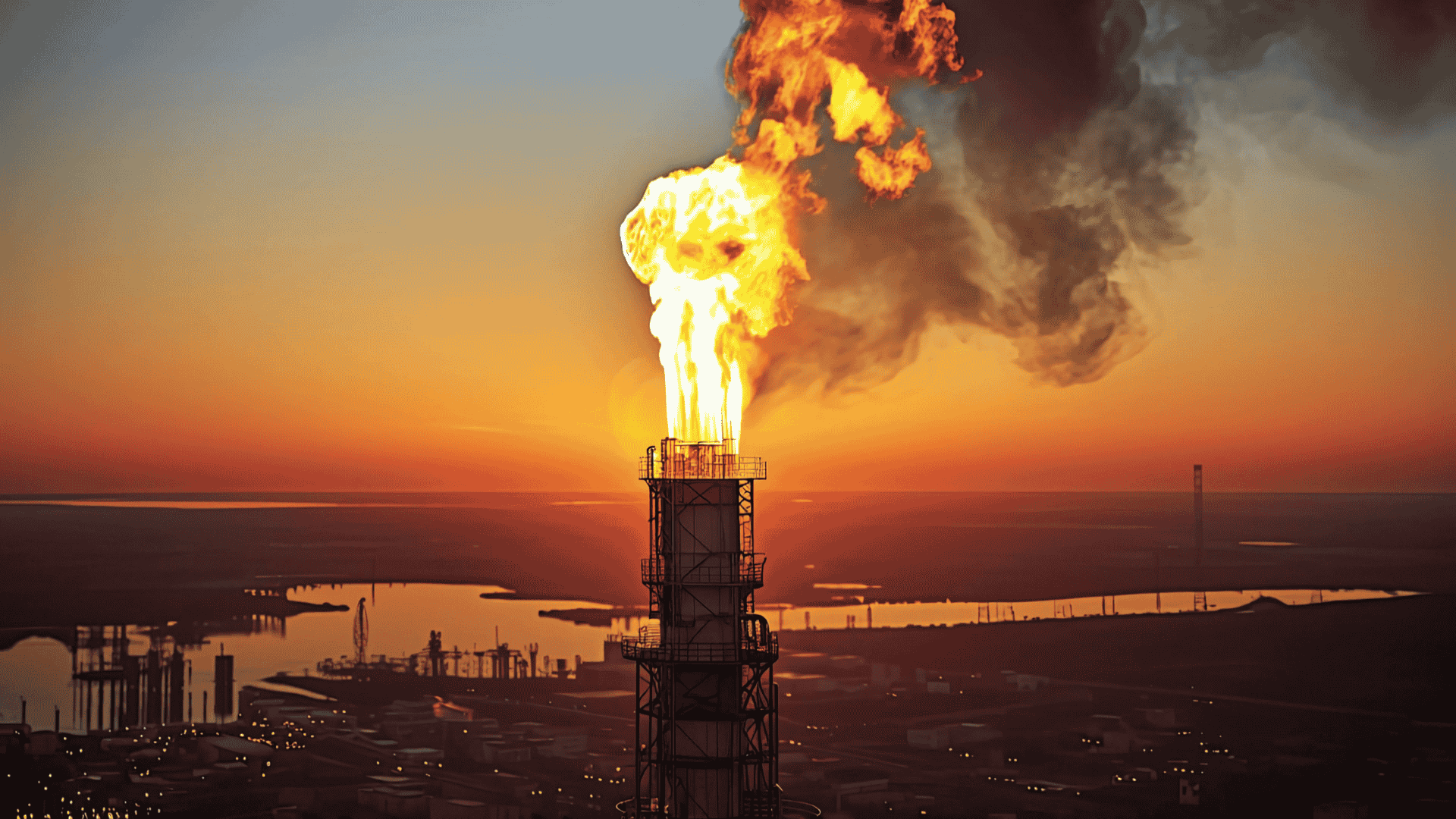

Flare Tips

As part of its diversified services provided to Refineries, Petrochemical and Chemical industries, Olayan Descon offers fabrication services for Flare Stack Tips required either as new or as replacement for damaged flare stack tips due to combustion of purge gases. Fabrication of all associated steam piping, and air-headers is carried out according to relevant standards. Qualified welders are deployed to produce highest standards of workmanship. Following services are provided for castable refractory:

- Surface Preparation

- Installation

- Curing (Hydrostatic setting)

- Drying out (Auxiliary Burners)

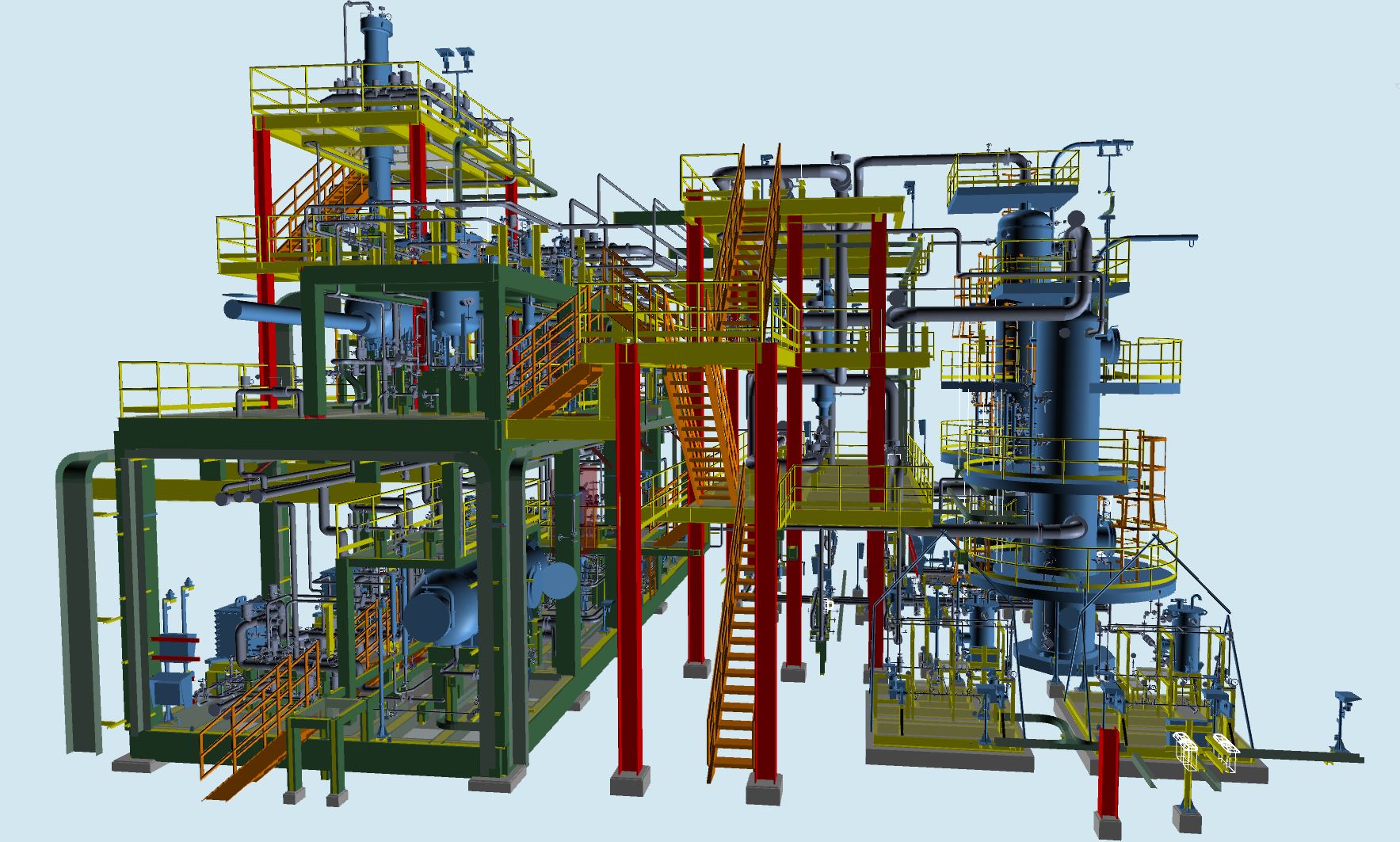

Modular Skid Packages

Olayan Descon offers expertise in fabricating Modular Skid Packages, providing high-quality solutions customized to client-specific designs. These compact, transportable units integrate multiple process systems, ensuring seamless installation and efficient operation. Dedicated to precision and quality, we transform your designs into reliable, cost-effective solutions for a wide range of industrial applications.